Solutions

Contact Us

- Tel : +86 18906343669

- Fax : +86 531 76778699

- Email : vivianxu@starringlw.com

- MSN:

- Skype:Whatsapp:008618906343669

-

Home > Waterproofing Membranes > TPO Waterproofing Membrane

|

|

||||||||||||||||

- Description

- Features

- Application

- Technical Parameters

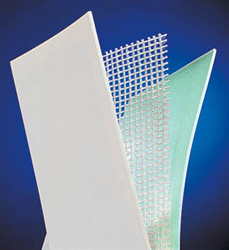

TPO waterproofing membrane which is a new-type waterproof material manufactured using state-of-the-art polymer manufacturing technology combines both polypropylene (plastic) and ethylene-propylene (rubber).Plasticizer-free TPO membrane deliver long-term flexibility. The result is an ideal commercial waterproofing membrane that is reliable, cost effective, environmentally friendly and easy to install.

1. High UV-resistance and high reflectivity

2. Excellent weathering characteristics and long-term flexibility

3. High tensile strength and puncture resistance

4. Excellent resistance to harsh chemicals and industrial pollutants

5. Heat or solvent-welding effectively provides seamless roof coverings

TPO waterproofing membrane is widely used in waterproofing engineerings such as roof, basement, water conservancy, dam, tunnel, supermarket and workshop, etc.

|

No. |

Test Item |

Indicators |

||

|

Code P |

||||

|

1 |

The thickness of resin layer above the reinforcement fabric mm≥ |

0.40 |

||

|

2 |

Stretching Performance |

Maximum Tension N/cm ≥ |

250 |

|

|

Max.Tension Elongation%≥ |

15 |

|||

|

3 |

Heating Treatment Size Change Rate%≤ |

0.5 |

||

|

4 |

Low-temperature Bending |

-40℃ No Craze |

||

|

5 |

Water Impermeability |

0.3Mpa,2h Water Impermeability |

||

|

6 |

Impact Resistance |

0.5kg·m , Water Impermeability |

||

|

7 |

Anti-static Loada |

20kg Water Impermeability |

||

|

8 |

Seam Peel Strength N/mm ≥ |

3.0 |

||

|

9 |

Trapezoid Tear Strength N≥ |

450 |

||

|

10 |

Water Absorbing Capacity (70℃168h)% |

After Soaking ≤ |

4.0 |

|

|

After Airing≥ |

-0.40 |

|||

|

11 |

Heat aging(80℃) |

Time |

672h |

|

|

Appearance |

No blisters, cracks, delamination, bonding and holes |

|||

|

Tensile Strength (max. tensile)Retention%≥ |

90 |

|||

|

Elongation Retention %≥ |

90 |

|||

|

Cold Bending |

-40℃, No Craze |

|||

|

12 |

Chemical Resistance |

Appearance |

No blisters, cracks, delamination, bonding and holes |

|

|

Tensile Strength (max. tensile)Retention %≥ |

90 |

|||

|

Elongation Retention%≥ |

90 |

|||

|

Cold Bending |

-40℃ No Craze |

|||

|

13 |

Artificial climate accelerating ageing |

Time |

1500hb |

|

|

Appearance |

No blisters, cracks, delamination, bonding and holes |

|||

|

Tensile Strength (max. tensile)Retention %≥ |

90 |

|||

|

Elongation Retention %≥ |

90 |

|||

|

Cold Bending |

-40℃ No Craze |

|||