Solutions

Contact Us

- Tel : +86 18906343669

- Fax : +86 531 76778699

- Email : vivianxu@starringlw.com

- MSN:

- Skype:Whatsapp:008618906343669

-

Home > Geosynthetics > Geomembrane > PVC Geomembrane

|

|

||||||||||||||||||

- Description

- Features

- Application

- Technical Parameters

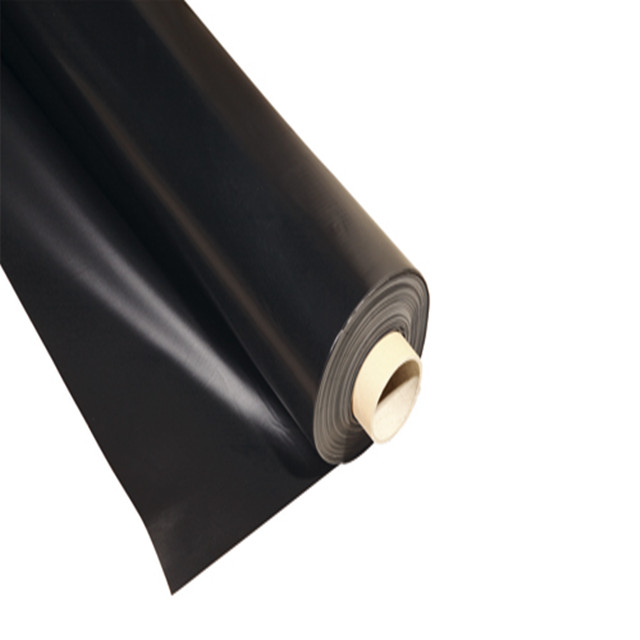

Polyvinyl Choride (PVC) Geomembrane

1.Products Description

The PVC waterproofing rolls formulas are based upon polyvinyl chloride resin with other assistants added to provide flexibility and stability such as anti-oxidant,absorbent of ultraviolet light, plasticizer and plastic filling agent.

2.Products Specification

|

Name |

Thickness(mm) |

Width(m) |

Length(m) |

|

PVC Geomembrane |

0.5-2.0 |

2 |

20M |

3.Physical Properties

PVC Physical Properties GB/T 17688-2009

|

|

Item |

Indicator |

|

1 |

Density(g/cm3) |

1.25-1.35 |

|

2 |

Tensile strength Mpa |

≥15/13 |

|

3 |

Breaking elongation % |

≥220/200 |

|

4 |

Tearing strength N/mm |

≥40 |

|

5 |

Low temperature bend |

-20℃ No cracking |

|

6 |

Dimensional change% |

≤5 |

|

7 |

Hydrostatic pressve Mpa≥ |

1.00 |

|

8 |

Permeability cm/s |

≤10-11 |

|

9 |

Permeability coefficient(cm3*cm) |

As design |

|

10 |

Appearance |

No blister,flaw,delamination,coherence,hole |

|

Tensile strength retention,% |

≤25 |

|

|

Elongation rate of keeping,% |

≤25 |

|

|

Low temperature bend |

-20℃No crack |

4.Application Range

PVC membranes form an effective barrier to liquid water or water vapor in the roof construction for industrial and civil engineering, underground engineering such as subway & tunnel, water conservancy such as water pools & ditch, shelter, grain depot, land filling, dyke, sewage treatment and basement.

Application Range

PVC membranes form an effective barrier to liquid water or water vapor in the roof construction for industrial and civil engineering, underground engineering such as subway & tunnel, water conservancy such as water pools & ditch, shelter, grain depot, land filling, dyke, sewage treatment and basement.

PVC Physical Properties GB/T 17688-2009

|

|

Item |

Indicator |

|

1 |

Density(g/cm3) |

1.25-1.35 |

|

2 |

Tensile strength Mpa |

≥15/13 |

|

3 |

Breaking elongation % |

≥220/200 |

|

4 |

Tearing strength N/mm |

≥40 |

|

5 |

Low temperature bend |

-20℃ No cracking |

|

6 |

Dimensional change% |

≤5 |

|

7 |

Hydrostatic pressve Mpa≥ |

1.00 |

|

8 |

Permeability cm/s |

≤10-11 |

|

9 |

Permeability coefficient(cm3*cm) |

As design |

|

10 |

Appearance |

No blister,flaw,delamination,coherence,hole |

|

Tensile strength retention,% |

≤25 |

|

|

Elongation rate of keeping,% |

≤25 |

|

|

Low temperature bend |

-20℃No crack |