Solutions

Contact Us

- Tel : +86 18906343669

- Fax : +86 531 76778699

- Email : vivianxu@starringlw.com

- MSN:

- Skype:Whatsapp:008618906343669

-

Home > Geosynthetics > Geomembrane > EPDM Pond Liner

|

|

||||||||||||||||||

- Description

- Features

- Application

- Technical Parameters

(OP)EPDM Rubber Waterproofing membranes

Description

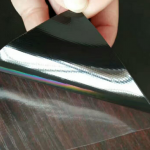

(OP)EPDM Rubber Waterproofing membranes is a synthetic rubber, synthetic tire blends as the base material, adding reinforcing agents, softeners, antioxidants, curing agents processing aids to promote mixing by kneading, mixing, extrusion, rolling and curing, shaping and other processes can be processed into sheet curling volume of new high elastic waterproof material.

Features

l Excellent weather-ability, durability and size stability

l Good adaptability to high and low temperature, UV resistant and anti-corrosion

l High tensile strength and good elongation, accommodating to structure movement

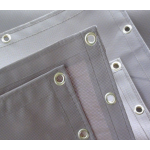

l Easy installation, solid joint, and no environmental pollution

l Good rooting penetration resistance

l Service life up to 50 years

Applications

l Roofs, Basements, Tunnels

l Industrial and civil building waterproofing

l Geosynthetic liner for fish ponds, swimming pools, channels, irrigation system.

l Especially suitable for projects with high requirement in durability, anti-corrosion and deformation

Specification

|

Type |

EPDM Rubber Waterproof Membrane |

||

|

Type |

Vulcanized and Weldable |

||

|

Thickness |

1.2mm |

1.5mm |

2.0mm |

|

Weight(kg/m2) |

1.54-1.58 |

1.79-1.83 |

2.25-2.29 |

|

Size |

1.2m (width) * 20m (length)/roll. Weldable type could be 8m wide. |

||

|

Packing |

24㎡/roll, with plastic bag. (Weldable: 80㎡/roll) |

||

|

Usage |

Roof, basement, pond, Lake, steel structure roofing, underground, tunnel, etc |

||

Technical Standard (GB standard)

|

NO. |

Item |

Unit |

Technical requirement |

|

|

1 |

Tolerance on size |

Thickness |

% |

±10 |

|

Width |

% |

±1 |

||

|

length |

% |

Does not allow negative |

||

|

2 |

Fracture tensile strength (normal temperature ) |

Mpa |

≥7.5 |

|

|

Fracture tensile strength(60 ℃) |

Mpa |

≥2.3 |

||

|

3 |

Breaking elongation,(normal temperature ) |

% |

≥450 |

|

|

Breaking elongation,(-20 ℃) |

% |

≥200 |

||

|

4 |

Tearing resistance |

KN/m |

≥25 |

|

|

5 |

Impermeability |

* |

0.3Mpa impermeable |

|

|

6 |

Bending at low temperature |

°C |

≤-40 |

|

|

7 |

Elongation and contraction volume at heating |

Elongation |

mm |

≤2 |

|

contraction |

mm |

≤4 |

||

|

8 |

Hot air aging 80°CX168h |

Fracture strength retention |

% |

≥80 |

|

Rate of elongation at break |

% |

≥70 |

||

|

9 |

Alkaline (saturated Ca(OH)2 solution normal Temperature x2 168h ) |

Fracture strength retention |

% |

≥80 |

|

Rate of elongation at break |

% |

≥80 |

||

|

10 |

Ozone aging (40 degree by 168 hours ) |

Elongation 40% , 500x10-2 | ||